Biogas Plant Types and Design

Digester types in industrialized countries

To give an overview, we have chosen

three fictitious designs as they could be

found in, for example, Europe. The

designs are selected in a way that all the

typical elements of modern biogas

technology appear at least once. All

designs are above-ground, which is

common in Europe. Underground

structures, however, do exist.

Mixing pit varies in size and shape

according to the nature of substrate. It is

equipped with propellers for mixing

and/or chopping the substrate and often

with a pump to transport the substrate

into the digester. At times, the substrate

is also pre-heated in the mixing pit in

order to avoid a temperature shock

inside the digester.

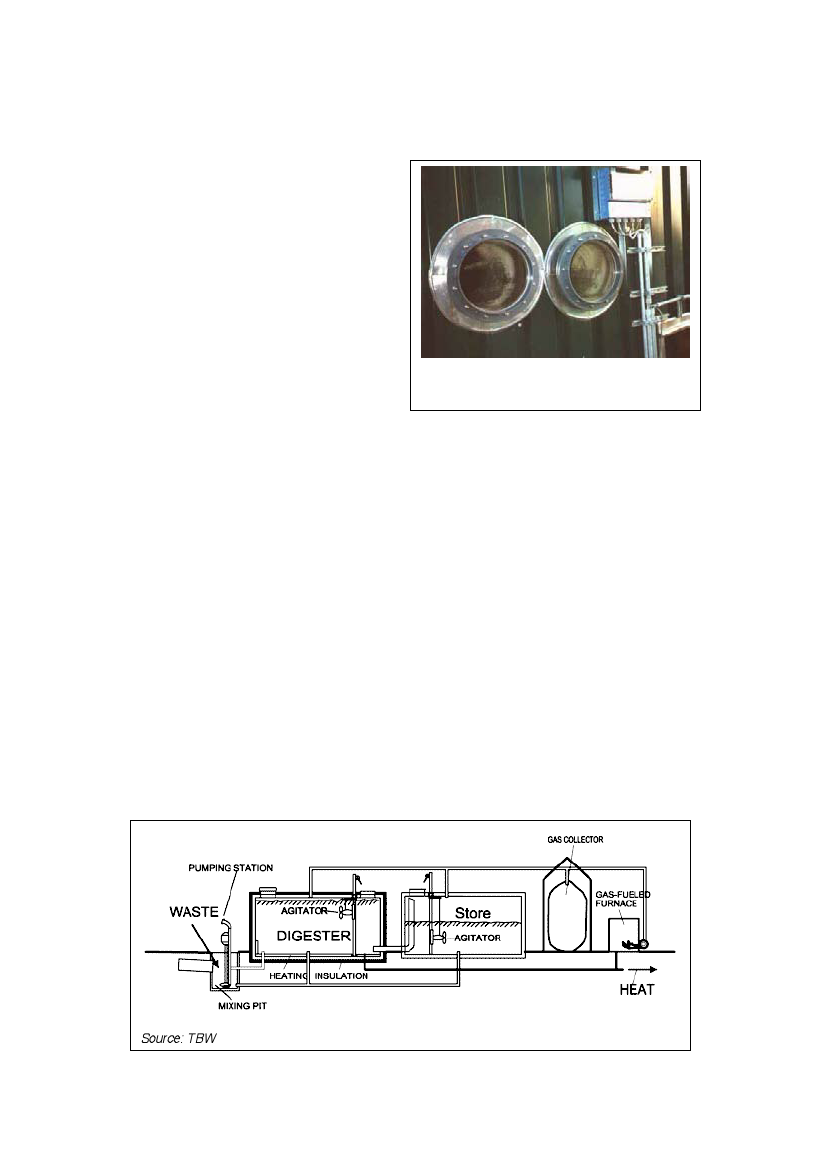

Figure 11: Control glasses for an industrial

digester for solid organic waste, TBW,

Germany

Fermenter or digester is insulated and made of concrete or steel. To optimize the flow of

substrate, large digesters have a longish channel form. Large digesters are almost always

agitated by slow rotating paddles or rotors or by injected biogas. Co-fermenters have two or

more separated fermenters. The gas can be collected inside the digester, then usually with a

flexible cover. The digester can also be filled completely and the gas stored in a separate

gas-holder.

Gas-holder is usually of flexible material, therefore to be protected against weather. It can

be placed either directly above the substrate, then it acts like a balloon plant, or in a separate

’gas-bag’.

slurry store for storage of slurry during winter. The store can be open (like conventional

open liquid manure storage) or closed and connected to the gas-holder to capture remaining

gas production. Normally, the store is not heated and only agitated before the slurry is

spread on the field.

Gas use element is in Europe in 95% of the cases a thermo-power unit which produces

electricity for the farm, the grid and heat for the house, greenhouses and other uses. The

thermo-power unit has the advantage, that the required energy can be produced in any

mixture of gas and fossil energy. It can, therefore, react to periods of low gas production and

high energy requirements or vice versa.

Figure 12: Concrete digester with two chambers (one heated, one unheated for storage)

Source: TBW

15